EBMUD

East Bay Municipal Utility District (EBMUD) is a trusted provider of essential services to over 1.4 million residents in the East Bay area of Northern California. Their core services include:

- High-quality drinking water

- Wastewater treatment

- Water conservation

- Watershed protection

They own and operate 4,200 miles of water lines, have a 10% water loss rate, and rehabilitate 25 miles per year of their water system for a cycle time of 162 years. EBMUD has used high-density polyethylene (HDPE) pipe for at least 20 years, experimenting with smaller diameter mains and service lines before moving into larger diameter and more consequential projects.

Early setbacks with HDPE were addressed by the Alliance for PE Pipe and industry partners, who held a summit at EBMUD headquarters several years ago. Following that meeting, EBMUD trained maintenance crews as fusion technicians so they knew how to properly fuse and handle HDPE pipe. Additionally, the engineering department adjusted their specifications to include proper fusion tech training as a requirement for contractors.

Prior to the summit, EBMUD contractors were not required to have fusion credentials, so a large number of electrofusions and flange connections were not made properly. Once EBMUD confirmed proper procedures, HDPE became more well respected and consequently it was used more frequently.

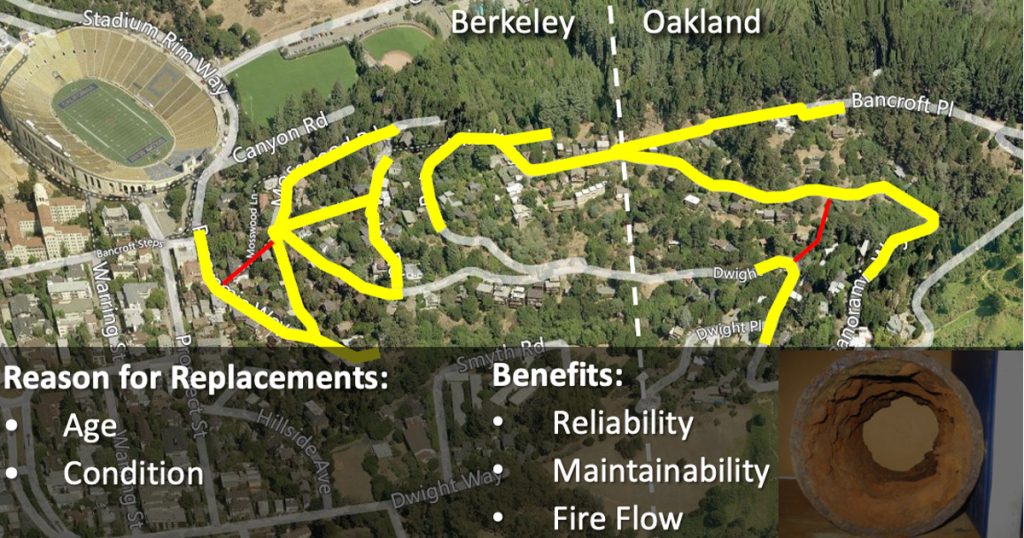

One of the ensuing projects was a particularly well-suited project for HDPE. It was entitled “Panoramic View of a Water Main Replacement Project in a Fire-Seismic Geohazard Zone.” This 7,800′ of 2-12″ HDPE DR 11 pipe project was put in on time and on budget. The project called for significant elevation change, was located immediately adjacent to a fault line in a seismic zone and required tight turns necessitating field bending of the HDPE pipe strings. EBMUD engineer and project manager Krista Moita PE was subsequently invited to present the project at Plastic Pipes XIX. The Panoramic View project is a prime example of why HDPE is the best pipe for many challenging applications. It is strong, durable, and flexible, making it ideal for use in seismic areas. Additionally, it is relatively lightweight and easy to install, which can save time and money on large projects.

Illustration: image from helicopter seismic project