2022 Awards

2022 – First Time User

May City IA Water

16 Miles 6” – 12” DR11

Awarded to: WL Plastics

Submitted by: Richard Kolasa

Participating Members: McElroy Manufacturing

The project was undertaken to add capacity to the May City Iowa’s water supply to accommodate high demand during summer periods. A total of sixteen miles of 12” will be installed with, 6” and 8” laterals for a total of 93,000 linear feet. Eight miles were fused in less than three months. Designers of this project, which originally specified PVC, became convinced that HDPE could dramatically improve the efficiency of installation, minimal disruption, and superior longevity.

2022 – Creative Trenchless Installation

City of Fort Lauderdale Force Main HDD

7.5 Miles 48” – 54” DR17

Awarded to: Murphy Pipelines

Submitted by: Todd Grafenauer

Participating Members: McElroy Manufacturing, ISCO Industries, Consolidated Pipe

Following the catastrophic release of millions of gallons of raw sewage into the intercoastal waterway, the city of Fort Lauderdale needed an immediate solution. Utilizing 17 large directional drills, this fast-tracked emergency design-build project is among the most ambitious trenchless projects ever undertaken in an urban environment. With flow capacity of 64 million gallons per day, the new Fort Lauderdale 7.5 mile sewer force main, installed primarily utilizing horizontal directional drilling, and 48” and 54” HDPE, crosses two canals, the Intercoastal Waterway, and several major county and Florida DOT roadways.

2022 – Environmental Sustainability

Powell River BC Wastewater Treatment Plant

7 Miles 4” – 48” HDPE Pipe

Awarded to: ISCO AH McElroy

Submitted by: Jeff Lore

Participating Members: McElroy Manufacturing, Infra Pipe, Dow Chemical

The Powell River WWTP exemplified a total overhaul in what was previously specified as a PVC and DI project and a dedicated approach to use HDPE for its sustainable infrastructure qualities. Through the contractor, Graham Infrastructure and Koers & Associates, the PVC C900 and DR18 was redesigned to HDPE DR11, DR17 and DR21 for all the water and sewer pipe to accommodate an HDD approach to install and minimize ground disturbance through the roadways of the city of Powell River, BC. At the same time, the Powell River WWTP was required to install a new outfall to replace the aging concrete treated sewer outfall. A unique challenge with the local marine life in the area and the alignment during install. All elements of the project proved successful. In conjunction with Dell Doyle and his submission as part of the DOW resin being used to manufacturer the HDPE pipe.

2022 – First Time User

Okeechobee Florida Utility Authority

23,000’ 12” DR 11 FM HDPE Pipe

Awarded to: Core & Main

Submitted by: Caleb Graham

Participating Members: McElroy Manufacturing, WL Plastics

This SWSA Master Force Main was the first HDPE project for the Okeechobee Florida Utility Authority. Over 23,000 feet of 12” DIPS DR 11 green stripe was installed ahead of the project deadline. Both butt fusion and electrofusion played an important role in the delivery of the project to the Okeechobee Florida Utility Authority.

2022 – National Government Leadership

Government of Bermuda, Water & Sewage section of the Ministry of Public Works

30 miles of HDPE Pipe various diameters to date

Awarded to: Government of Bermuda

Submitted by: Juan Quintero and McElroy Manufacturing

Participating Members: McElroy Manufacturing

The Alliance bestowed upon the Government of Bermuda, Water & Sewage section of the Ministry of Public Works, The National Government Leadership Award for their trial, adoption and deployment of HDPE pipe. The use of HDPE pipe and system will significantly lower Bermuda’s water loss rate, provide leak-free sewage conveyance and improve quality of life on the island nation. The island does not have any natural rivers, aquifers or lakes so they must desalinate water from the ocean and collect water as it falls. They treat every drop of water with tremendous care in all of their actions. This process and result driven by the Bermuda Water & Sewage section serves as a model process for island nations everywhere in the world. Acknowledgement to Steven Tucker and the Bermuda Land Development Company for assisting the Water & Sewerage Section in the installation of the plan.

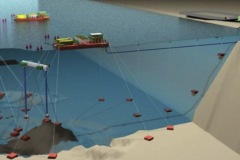

2022 – Environmental Sustainability

Lake Kivu in Rwanda

12” up to 54” HDPE pipe

Awarded to: ISCO Industries

Submitted by: Heather Leber

The African country of Rwanda is a landlocked nation with limited natural resources and power sources. Lake Kivu in Rwanda is one of the deepest fresh water lakes in the world, and contains enormous amounts of dissolved carbon dioxide gas trapped with methane – a potentially deadly combination. With engineering and technical expertise provided by ISCO, and utilizing the unique flexibility and corrosion resistant properties of HDPE pipe, The Shema Power Lake Kivu utility, devised a way to extract methane gas from the lake and transport it 8 miles under water to the on-shore power plant where it is used as a green alternative fuel to produce electricity.

2022 – Innovative PE Solutions

Tolt Pipeline: Seattle 54” Water Supply

2500 feet of 54” DR 17 HDPE Slipline

Awarded to: ISCO Industries

Submitted by: Drew Mueller

The city of Seattle has hosted two roadshows, a training sessions and two seminars over the last few years. They have now trialed HDPE pipe on several distribution projects. They are now ready for larger and more consequential applications of HDPE pipe. The South Fork Tolt River is the smaller and lesser known but still essential second supply watershed in Seattle Public Utilities’ freshwater supply system. Located in the foothills of the Cascades in east King County, it supplies about 30% of the drinking water for 1.5 million people in and around Seattle. One of two redundant raw water lines had been abandoned for several years due to failing concrete pipe and concerns about further damage due to seismic events and the liquification of soils in the Cascade foothills. Utilizing slip-lining and 2500 feet of 54” DR 17 HDPE, this project is providing the city with a reliable raw water pipeline.

2022 – Creative Trenchless Installation

City of Rochester Hills, MI

25,000’ 10” DR 11 HDPE Pipe

Awarded to: Core & Main

Submitted by: David Mosier

Participating Members: McElroy Manufacturing, WL Plastics

Utilizing 10” HDPE and trenchless installation, this project involved the replacement and upsizing of 25,000 feet of aging asbestos cement and cast iron water mains, replacement of 352 service connections using 1” HDPE, and numerous valves and hydrants installed in the 1960’s in two residential neighborhoods in Rochester Hills Michigan. The Rochester Hills Public Utilities Engineering Manager stated, “The pre-chlorinated pipe bursting method with HDPE has become a favorite water main replacement method in Rochester Hills in recent years based on the integrity of the pipe, minimal disruption to our residents’ water service and properties and the ability to upsize our water main. We were able to replace 6-inch and 8-inch cast iron and AC water main with 10-inch HDPE SDR 11 pipe. 6-inch water main is no longer a permitted public water main size and it’s been beneficial to be able to upsize the water main in well-established subdivisions in the same location as the existing water main and with minimal disruption to landscaping, roads, sidewalks, etc. This method minimizes customer complaints and typically results in many compliments as well.”Hundreds of thousands of feet of asbestos cement pipe, installed during the post-war building boom of the 1950’s and 60’s, are still in the ground and in use in potable water systems in the U.S. This pipe has exceeded its 50-year design life and needs to be replaced, and often upsized, to meet current water needs.